- E-mail: viktor@duc-energy.dk

- Phone: +45 28 53 54 78

- Viber/Whatsapp: + 45 28 53 54 78

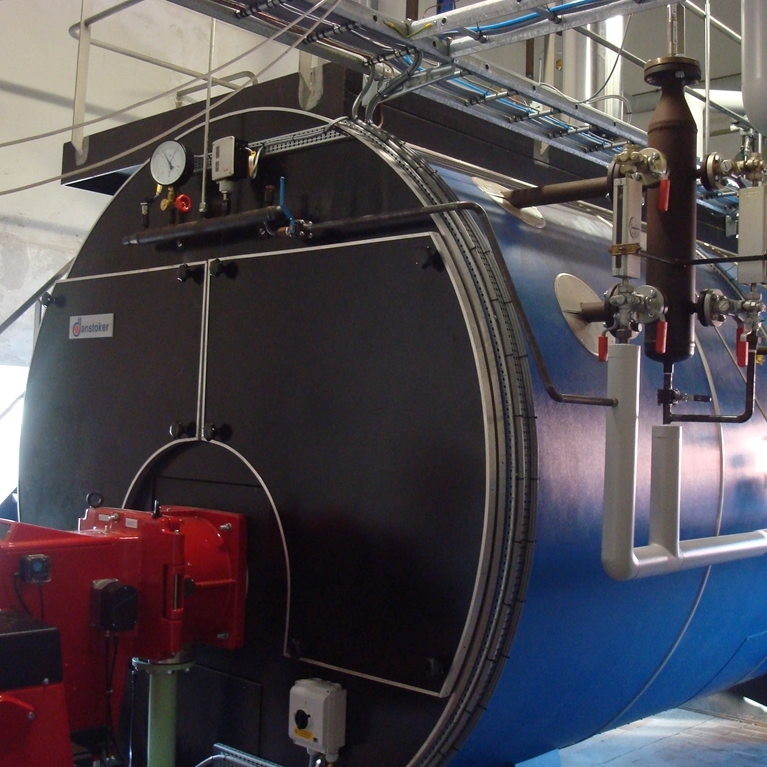

Since the outset in 1935, Danstoker has developed into a company whose name is synonymous with high-performance boilers for the international energy sector. Domiciled in Denmark – a country renowned for its far-sighted energy policy – Danstoker’s own policy has been to constantly engage in intensive product development and constructive dialogue with the market players, i.e. combined efforts that have resulted in technical innovation and extensive experience.

Since the outset in 1935, Danstoker has developed into a company whose name is synonymous with high-performance boilers for the international energy sector. Domiciled in Denmark – a country renowned for its far-sighted energy policy – Danstoker’s own policy has been to constantly engage in intensive product development and constructive dialogue with the market players, i.e. combined efforts that have resulted in technical innovation and extensive experience.

With more than 80 years’ experience, Danstoker’s employees have accumulated extensive expertise within development, design and construction of boilers according to the applicable, frequently changing standards and regulations.

This is reflected in the company’s many internationally renowned reference plants. The specific needs of our clients are a constant priority of ours, which Danstoker is happy to accommodate, whether the job is one of minor adjustments of our standard boilers or of major design changes necessitated by the choice of fuel or the building layout.

Danstoker's wide product range covers most applications – for hot water, high temperature hot water or steam – with shell and tube or water tube boilers

- Oil/gas

- Biomass fired boilers

- Recovery of waste heat (e.g. WHRB or cogeneration)

- Electric boilers

- Absorption heat pumps

- All complemented by a wide range of ancillary equipment on demand.

Danish design and professional pride are your guarantee for a high quality level every step of the way from quote, sales, technical design and construction, to production and project management. Furthermore, Danstoker is certified according to ISO9001 and ISO3834.

Danstoker can supply boilers according to most applicable standards, e.g. EN, ASME, ISI, and GOST.

Danstoker focuses on environmental awareness and the shortage of resources. Every boiler is adapted to suit the specific characteristics of the fuel used.

The optimal result is achieved in a close co-operation with the world’s leading suppliers of combustion and fuel-handling equipment.

The optimal result is achieved in a close co-operation with the world’s leading suppliers of combustion and fuel-handling equipment.

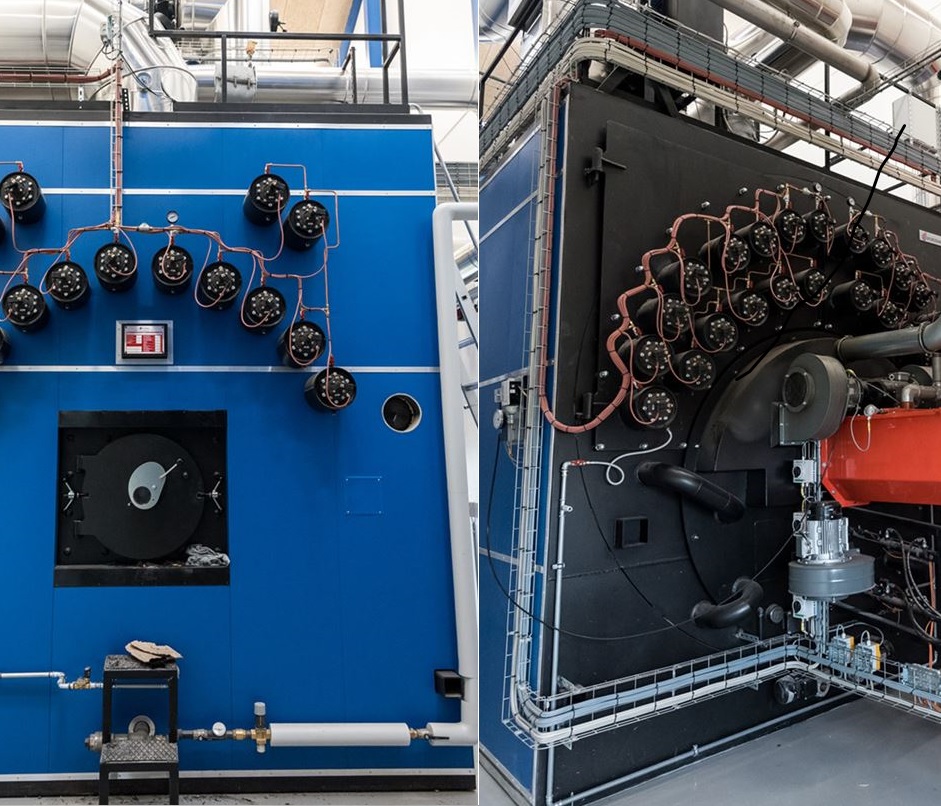

Danstoker develops and supplies customized boilers tailored to the particular layout of each plant, and/or to alternative fuels.

Types: Steam and hot water/high pressure hot water boilers, shell and tube boilers, box and water tube boilers

Fuels: Biomass/solid fuel

Steam rating (kg/h): Up to 68,000 kg/h

Heat capacity (kW): Up to 50,000 kW

Pressure: 4 to 43 bar-g, depending on the design

Our boilers are usually equipped with Danstoker’s automatic pneumatic cleaning system - Danblast

Typical fuels include:

- Wood chips, forest residue, bark, sawmill/construction waste

- Saw dust, wood pellets, fruit stones

- Straw, agrifibres, etc.

- Conventional solid fuels

Over the past few decades, Danstoker has delivered more than 2,500 exhaust gas boilers worldwide and has gained an unparalleled expertise in this field. The boilers are fitted after gas or diesel engines or gas turbines. In order to extend the cleaning intervals, Danstoker maintains a deliberate focus on the production of shell and tube based exhaust gas boilers. Danstoker’s exhaust gas steam boilers are supplied as single or double pass boilers with integrated economizers and/or superheaters.